Box Column

Specific drawings will differ and change. Some are like a "#" shape, with all sides coming out, some are like a "mouth", and of course there are also semi-sealed ones. Therefore, you must have drawings when processing box columns, and some also need to add some ribs and the like inside the columns.

Category:

Steel Components

Key words:

Box Column

CONTACT US

PRODUCT DESCRIPTION

It is named because it is shaped like a large iron box. Generally used as beams or columns on steel structures.

Specific drawings will differ and change. Some are like a "#" shape, with all sides coming out, some are like a "mouth", and of course there are also semi-sealed ones. Therefore, you must have drawings when processing box columns, and some also need to add some ribs and the like inside the columns. Some people also use large square and rectangular tubes instead of box columns. However, due to production capacity limitations, the thickness often does not meet the requirements. Most box columns are submerged arc welded.

The box column is named after its shape like a large iron box. Generally used as beams or columns on steel structures. Specific drawings will differ and change. Some are like a "#" shape, with all sides coming out, some are like a "mouth", and of course there are also semi-sealed ones. Therefore, you must have drawings when processing box columns, and some also need to add some ribs and the like inside the columns. Some people also use large square and rectangular tubes instead of box columns. However, due to production capacity limitations, the thickness often does not meet the requirements. Most box columns are made by submerged arc welding. One of the three seams requires special welding, which is more difficult. General domestic steel structure factories can do it, but each has a different quotation.

box column

The box column is welded by four steel plates. The manufacturing process is roughly the same as that of welding H-shaped steel. The process is shown in the flow chart.

The box-shaped column is blanked using a CNC flame cutting machine to cut the column plate. The beveling method is carbon arc gouging to cut a K-shaped groove. After the blanking is completed, it is straightened and corrected. In order to ensure that the column body plate is assembled accurately, an assembly tire needs to be prepared. Membrane, the assembly sequence is: first, the upper cover plate is used as the basis, then the assembly line of the diaphragm and side web plates is released, and the U-shaped assembly is carried out. Finally, the lower cover is assembled and welded after the assembly is completed. The main body of the column is welded by submerged arc automatic welding. , the stiffening plate is welded manually with an electric welding machine, and the last partition plate is welded by electroslag pressure welding, and an arc ignition plate is provided for welding. The production and assembly of box columns is the key. The assembly process is as follows:

1. First, the upper cover plate is used as the assembly reference. On the assembly surface, the partition and side web assembly lines are laid out according to the requirements of the construction drawing, and marked with sample punches.

2. First assemble the upper cover and partition, and assemble them on the tire mold. After assembly, welding must be completed before proceeding to the next process.

3. Before assembling the web, the straightness of the web must be checked. During assembly, assemble in one direction. Position the middle stiffening plate first and then the web.

4. The overall assembly of the box structure is carried out after the U-shaped structure is completed. First, correct the edge of the web of the U-shaped structure to make the unevenness <L/1000. Then release the web assembly positioning line on the lower cover plate, flip it over and match the U-shaped structure. The structure is assembled in one direction, and the positioning spot welding adopts symmetrical welding method.

5. The last side of the partition is welded by electroslag pressure welding using special equipment.

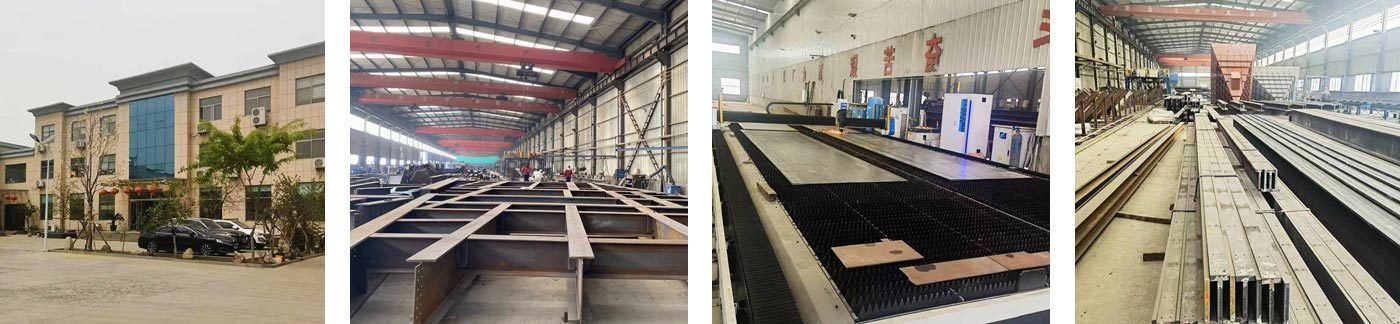

FACTORY

It is a professional company that produces products such as profile steel, gantry channel steel, and track steel. The company has a registered capital of 10 million yuan and possesses advanced production equipment and a professional technical team, committed to providing customers with high-quality products and services.

APPLICATION AREAS

The company's main products include various specifications of section steel, gantry channel steel, track steel, etc., which are widely used in construction, machinery manufacturing, shipbuilding and other fields.

PACKING AND SHIPPING

The product quality is stable and reliable, receiving high praise from customers. The company has established long-term cooperative relationships with multiple well-known domestic and foreign enterprises, and its products are exported to overseas markets.

FAQ

Is it possible to customize steel structures with special shapes?

Yes, we can customize various special shaped steel structures according to customer requirements to meet the needs of different projects.

Are we a factory or a trader?

We are a factory specializing in the production of H-shaped steel, track steel, door frame channel steel, and steel structures, with excellent quality and sufficient supply of goods

Can we specify the freight and port?

Yes, and send the designated freight and port according to customer requirements

Is after-sales service provided?

Yes, we provide after-sales maintenance and consulting services for steel structures to ensure that our clients' projects can operate stably in the long term.

How to ensure the quality of steel structures?

We strictly follow national standards and industry norms in our design and manufacturing to ensure the quality and safety of steel structures.

What are the advantages of profile steel structures?

Profile steel structures have advantages such as light weight, high strength, fast construction speed, and strong durability, which can meet various building needs.

Related Products

Message