Hot rolled small customized products

Recrystallization means that when the annealing temperature is high enough and the time is long enough, strain-free new grains (recrystallization cores) are produced in the fiber structure of the deformed metal or alloy, and the new grains continue to grow until the original deformed structure is completely disappear, and the properties of the metal or alloy also change significantly.

Category:

Hot Rolled Finished Profiles

Key words:

Hot rolled small customized products

CONTACT US

PRODUCT DESCRIPTION

Hot rolling refers to rolling performed above the metal recrystallization temperature.

Recrystallization means that when the annealing temperature is high enough and the time is long enough, strain-free new grains (recrystallization cores) are produced in the fiber structure of the deformed metal or alloy, and the new grains continue to grow until the original deformed structure is completely disappear, and the properties of the metal or alloy also change significantly. This process is called recrystallization. The temperature at which new grains begin to be generated is called the starting recrystallization temperature. The temperature at which the microstructure is completely occupied by new grains is called Final recrystallization temperature, generally what we call recrystallization temperature is the arithmetic mean of the starting recrystallization temperature and the final recrystallization temperature. Generally, the recrystallization temperature is mainly affected by factors such as alloy composition, deformation degree, original grain size, and annealing temperature. Influence.

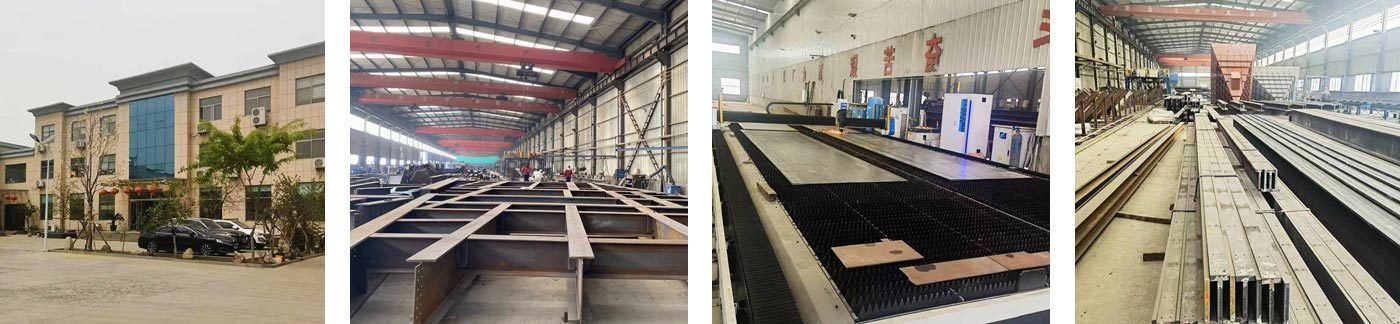

FACTORY

It is a professional company that produces products such as profile steel, gantry channel steel, and track steel. The company has a registered capital of 10 million yuan and possesses advanced production equipment and a professional technical team, committed to providing customers with high-quality products and services.

APPLICATION AREAS

The company's main products include various specifications of section steel, gantry channel steel, track steel, etc., which are widely used in construction, machinery manufacturing, shipbuilding and other fields.

PACKING AND SHIPPING

The product quality is stable and reliable, receiving high praise from customers. The company has established long-term cooperative relationships with multiple well-known domestic and foreign enterprises, and its products are exported to overseas markets.

FAQ

Is it possible to customize steel structures with special shapes?

Yes, we can customize various special shaped steel structures according to customer requirements to meet the needs of different projects.

Are we a factory or a trader?

We are a factory specializing in the production of H-shaped steel, track steel, door frame channel steel, and steel structures, with excellent quality and sufficient supply of goods

Can we specify the freight and port?

Yes, and send the designated freight and port according to customer requirements

Is after-sales service provided?

Yes, we provide after-sales maintenance and consulting services for steel structures to ensure that our clients' projects can operate stably in the long term.

How to ensure the quality of steel structures?

We strictly follow national standards and industry norms in our design and manufacturing to ensure the quality and safety of steel structures.

What are the advantages of profile steel structures?

Profile steel structures have advantages such as light weight, high strength, fast construction speed, and strong durability, which can meet various building needs.

Related Products

Message