H-beam

H-shaped steel is an economical cross-section and high-efficiency profile with more optimized cross-sectional area distribution and more reasonable strength-to-weight ratio. It is named because its cross-section is the same as the English letter "H".

Category:

Hot Rolled Finished Profiles

Key words:

H-beam

CONTACT US

PRODUCT DESCRIPTION

H-shaped steel is an economical cross-section and high-efficiency profile with more optimized cross-sectional area distribution and more reasonable strength-to-weight ratio. It is named because its cross-section is the same as the English letter "H". Since all parts of H-shaped steel are arranged at right angles, H-shaped steel has the advantages of strong bending resistance in all directions, simple construction, cost saving and light structural weight, and has been widely used.

The inner and outer sides of the flanges of H-shaped steel are parallel or close to parallel, and the flange ends are at right angles, hence the name parallel flange I-beam. The web thickness of H-shaped steel is smaller than that of ordinary I-beams with the same web height, and the flange width is larger than that of ordinary I-beams with the same web height, so it is also called wide-edge I-beam. Determined by its shape, the section modulus, moment of inertia and corresponding strength of H-shaped steel are significantly better than ordinary I-beams of the same unit weight. Used in metal structures with different requirements, it shows its superior performance whether it bears bending moment, pressure load, or eccentric load. It can greatly increase the load-bearing capacity compared with ordinary I-beams and save 10% to 40% of metal. H-shaped steel has wide flanges, thin webs, multiple specifications, and flexible use. It can save 15% to 20% of metal when used in various truss structures. Because the inner and outer sides of the flange are parallel and the edge ends are at right angles, it is easy to assemble and combine into various components, thus saving about 25% of the welding and riveting work, which can greatly speed up the construction speed of the project and shorten the construction period.

Usage: Due to the above advantages, H-shaped steel is widely used, mainly used in: various civil and industrial building structures; various large-span industrial plants and modern high-rise buildings, especially industrial plants in areas with frequent seismic activity and under high-temperature working conditions. ; Large bridges that require large load-bearing capacity, good cross-sectional stability, and large spans; heavy equipment; highways; ship frames; mine support; foundation treatment and dam engineering; various machine components.

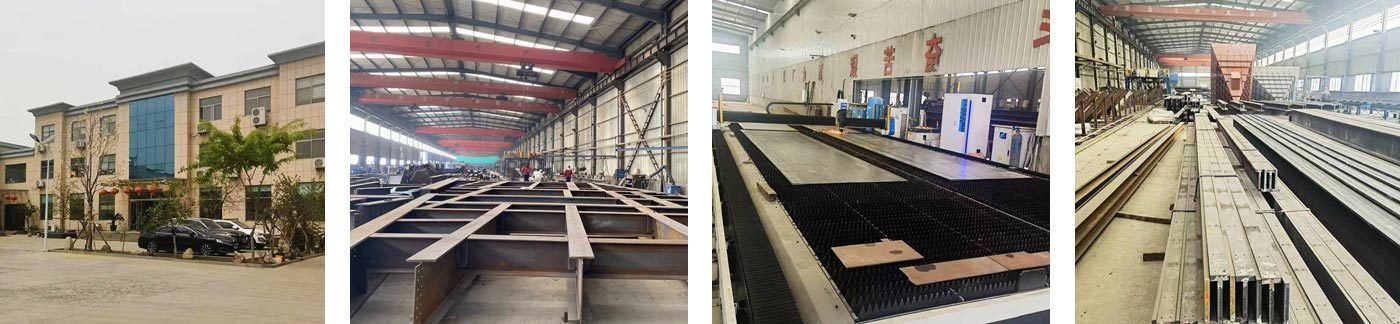

FACTORY

It is a professional company that produces products such as profile steel, gantry channel steel, and track steel. The company has a registered capital of 10 million yuan and possesses advanced production equipment and a professional technical team, committed to providing customers with high-quality products and services.

APPLICATION AREAS

The company's main products include various specifications of section steel, gantry channel steel, track steel, etc., which are widely used in construction, machinery manufacturing, shipbuilding and other fields.

PACKING AND SHIPPING

The product quality is stable and reliable, receiving high praise from customers. The company has established long-term cooperative relationships with multiple well-known domestic and foreign enterprises, and its products are exported to overseas markets.

FAQ

Is it possible to customize steel structures with special shapes?

Yes, we can customize various special shaped steel structures according to customer requirements to meet the needs of different projects.

Are we a factory or a trader?

We are a factory specializing in the production of H-shaped steel, track steel, door frame channel steel, and steel structures, with excellent quality and sufficient supply of goods

Can we specify the freight and port?

Yes, and send the designated freight and port according to customer requirements

Is after-sales service provided?

Yes, we provide after-sales maintenance and consulting services for steel structures to ensure that our clients' projects can operate stably in the long term.

How to ensure the quality of steel structures?

We strictly follow national standards and industry norms in our design and manufacturing to ensure the quality and safety of steel structures.

What are the advantages of profile steel structures?

Profile steel structures have advantages such as light weight, high strength, fast construction speed, and strong durability, which can meet various building needs.

Related Products

Message